وبلاگ

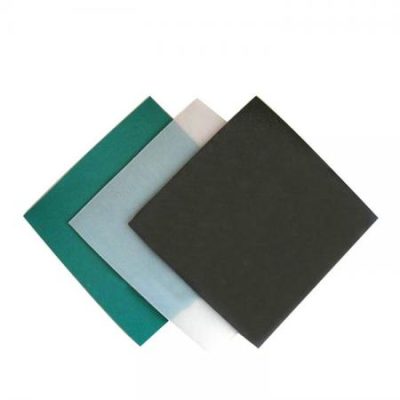

Checking and buying all types of geomembrane sheets

Geomembrane is a type of impermeable polymer coating that is widely used in various civil and environmental projects. These sheets are used to prevent the penetration of liquids, gases and other chemical substances, and in fact, they act as an effective barrier against the penetration of illegal substances into the soil and underground water sources. Geomembranes are usually produced from polyethylene, polyvinyl chloride and other synthetic polymers and have unique properties that make them an ideal option for use in various projects.

Key features of geomembranes:

Impermeability: Geomembranes are specifically designed to prevent the penetration of liquids, and this feature makes them widely used in water and chemical storage projects.

Chemical resistance: These sheets are resistant to corrosive chemicals and other environmental factors and are therefore used in the chemical and oil and gas industries.

Durability and Longevity: Geomembranes are typically long-lived and will not be damaged under various weather conditions, including UV, rain, snow, and cold and heat.

Light and Flexible: These sheets are easy to install and are malleable which makes them easy to install.

Compatibility with the environment: Due to their structure, geomembranes are known as an environmentally friendly option and can help preserve natural resources.

What are the types of geomembranes?

Geomembranes are generally divided into two main types: HDPE geomembranes and PVC geomembranes. Each of these types has its own characteristics and uses, which we will explain below.

HDPE geomembranes

HDPE (high density polyethylene) geomembrane is one of the most widely used types of geomembrane in the industry. Due to its special features, this type of sheet is used in many construction and agricultural projects.

Features and benefits of HDPE geomembranes:

Excellent chemical resistance: These sheets are very resistant to strong and corrosive chemicals, and for this reason, they are used to store chemicals and toxic materials.

UV resistance: HDPE geomembranes can work well in open environments due to their UV resistance and are not damaged.

Resistance to mechanical stress: These sheets are able to withstand pressure and mechanical stress and are resistant to perforation and tearing.

Easy installation: Due to the lightness and flexibility of these sheets, their installation is quick and easy. They can also be connected using a thermal welding machine.

Long life: These types of geomembranes usually have a long useful life and can be used for many years without the need for major repairs.

Applications of HDPE geomembranes:

Industrial and agricultural pools: It is used as a waterproof coating in pools.

Waste management: In landfill projects, it is used as a barrier to prevent hazardous materials from entering the soil.

Water catchers and reservoirs: It is used in water storage facilities and water catchers to prevent water infiltration into the soil and other underground resources.

PVC geomembranes

PVC (polyvinyl chloride) geomembrane is also one of the famous types of geomembrane, which is used in various projects due to its special features.

Features and benefits of PVC geomembranes:

High flexibility: These sheets have high flexibility and can be easily shaped into different shapes, which makes them useful in different projects.

Temperature resistance: PVC geomembranes can work well in low and high temperatures and are not damaged.

Reasonable price: Due to the easy production process and the low cost of raw materials, these types of sheets are usually more economical.

Dyeability: These sheets can be easily dyed, which can be useful in certain projects.

Resistance to decay: PVC geomembranes can be well resistant to atmospheric and environmental factors and do not suffer from decay.

Applications of PVC geomembranes:

Agricultural pools: It is used as a coating resistant to water penetration in agricultural pools.

Water catchers: used to store water and prevent evaporation.

Construction coatings: It is used in construction and infrastructure projects as a protective layer to prevent water penetration.

Comparison between HDPE and PVC geomembranes

| Feature | geomembranes HDPE | geomembranes PVC |

| Chemical resistance | very high | high |

| UV resistance | very high | average |

| Flexibility | Less than PVC | very high |

| price | higher | lower |

| useful life | longer | average |

conclusion

Ultimately, the choice between HDPE and PVC geomembranes depends on the specific needs and circumstances of your project. If you are looking for high strength and chemical resistance, HDPE geomembrane is the right choice. But if flexibility and reasonable price are priorities for you, PVC geomembranes will be a better choice.

By providing both types of geomembranes, Jovane Posh Parse Company can help you meet the needs of different projects. Using quality raw materials and advanced technologies, this company produces products with unique features that can help you in agricultural and industrial projects.

What is the geomembrane welding machine and what is its application?

The geomembrane welding machine is one of the key tools in the installation and implementation of geomembrane sheets. This device is used to connect the edges of geomembrane sheets and performs the welding process by creating heat and pressure. Due to this welding, the two edges of the sheet are connected to each other and an impermeable layer is created, which helps prevent the penetration of liquids and gases.

Types of geomembrane welding machines

Thermal welding machine:

This type of device melts and connects them by creating heat on the edges of the sheets. This type of welding is usually used in large and complex projects.

Electric welding machine:

This device uses electrical energy to generate heat. The welds produced with this machine are usually very strong and of good quality.

Pneumatic welding machine:

This type of device uses compressed air pressure for welding. This method is suitable for projects that require welding in special conditions.

Applications of geomembrane welding machine

Installation of industrial pools: It is used to create a waterproof and protective cover against the penetration of chemicals and liquids.

Covering greenhouses: It is used to prevent moisture from escaping and maintain temperature in the greenhouse environment.

Construction projects: It is used as a protective layer in large construction projects to prevent water from penetrating the ground.

Waste management: Used in landfill projects to prevent hazardous materials from entering the ground.

Industrial pool

As one of the key applications of geomembranes, industrial pools are designed to store water, chemicals and other liquids in various industries. These pools usually act as a resistant and waterproof structure that can not be damaged in various environmental conditions.

Features and benefits of industrial pools with geomembranes

Resistance to chemicals: These pools are able to store dangerous and corrosive chemicals, without the risk of their penetration into the soil.

Long lifespan: Using geomembranes in these pools increases their useful life and helps reduce maintenance costs.

Quick and easy installation: Installation of industrial pools using geomembranes is faster and easier than concrete pools.

Protection of underground water sources: These pools help to prevent pollution of underground water sources.

Applications of industrial pools

Water storage: to store water needed in industrial processes.

Storage of chemicals: To prevent chemicals from entering the environment.

Cooling systems: used as cooling tanks in industrial systems.

Agricultural pool

Agricultural ponds are also one of the other important applications of geomembranes. These pools are designed to store water for irrigation of agricultural crops and help to improve the management of water resources.

Features and benefits of agricultural ponds with geomembranes

Evaporation reduction: The use of geomembranes helps to reduce water evaporation in these pools and causes more water retention.

Stability and resistance: These pools are resistant to different weather conditions and can work effectively in adverse weather conditions.

Reducing irrigation costs: By preventing water wastage, irrigation costs are reduced.

Optimal management of water resources: These pools help farmers to manage their water resources well and prevent water wastage.

Applications of agricultural ponds

Water storage for irrigation: as a source of water for irrigation in low water seasons.

Control of plant growth conditions: maintaining humidity and temperature in pools helps to improve plant growth.

Protection of water sources: preventing pollution from entering underground water sources.

The difference between a concrete pool and a geomembrane pool

The differences between concrete pools and geomembrane pools can be examined based on their features, costs, construction time, and maintenance.

cost

Concrete pool: usually has a higher cost due to the need for more raw materials and complex construction steps.

Geomembrane pool: It costs less because it is faster and easier to install and uses more affordable raw materials.

construction time

Concrete pool: it is time-consuming and requires construction works and heavy equipment.

Geomembrane Pool: It is faster to install and generally takes less time.

maintenance

Concrete pool: it needs constant maintenance and repairs and may be damaged by water penetration.

Geomembrane pool: Due to its high resistance to environmental conditions, it requires less maintenance.

Durability and strength

Concrete pool: usually stronger, but may be damaged by water ingress.

Geomembrane pool: These pools can prevent water penetration well and at the same time have good durability.

conclusion

Choosing between a concrete pool and a geomembrane pool depends on the specific needs of the project and environmental conditions. Geomembrane pools with lower cost and faster construction time are suitable options for various projects. But concrete pools with greater strength will be a better choice for projects that require high resistance and durability.

Javaneh Poosh Parseh

Javaneh Poosh Parseh Company is one of the pioneers in the production of polymer products in Shiraz. Using new technologies and an experienced team, this company produces all kinds of geomembrane sheets, greenhouse nylon, greenhouse plastic and other related products. Our goal at Javaneposh Parse Company is to provide high quality products and services tailored to the needs of our customers.

Our products:

HDPE and PVC geomembrane sheets: excellent quality and resistant to chemicals and different weather conditions.

Greenhouse nylon: suitable for optimizing the growing conditions of plants and increasing the production of agricultural products.

Greenhouse plastic: to create a suitable environment for cultivation.

Shrink nylon: in order to package products and maintain their quality.

Agricultural plastic: with multiple applications in the agricultural industry.

Benefits of cooperation with Parse bud:

High quality: All our products are produced under international standards and are of high quality.

Expert team: Our technical and consulting team is ready to help you choose the best products and solutions.

After-sales service: We provide excellent after-sales service to our customers and will always be by your side.

contact us

For more information about products, services and expert advice, you can contact us. Our support team is ready to answer your questions and needs.

Contact information:

Phone: 09017606868 07137742366-9

Address: Big Industrial City of Shiraz, Sooreh Square, South Sooreh Blvd., 203 St.

Website: javanehpoosh.com